steel wire rope

steel wire rope

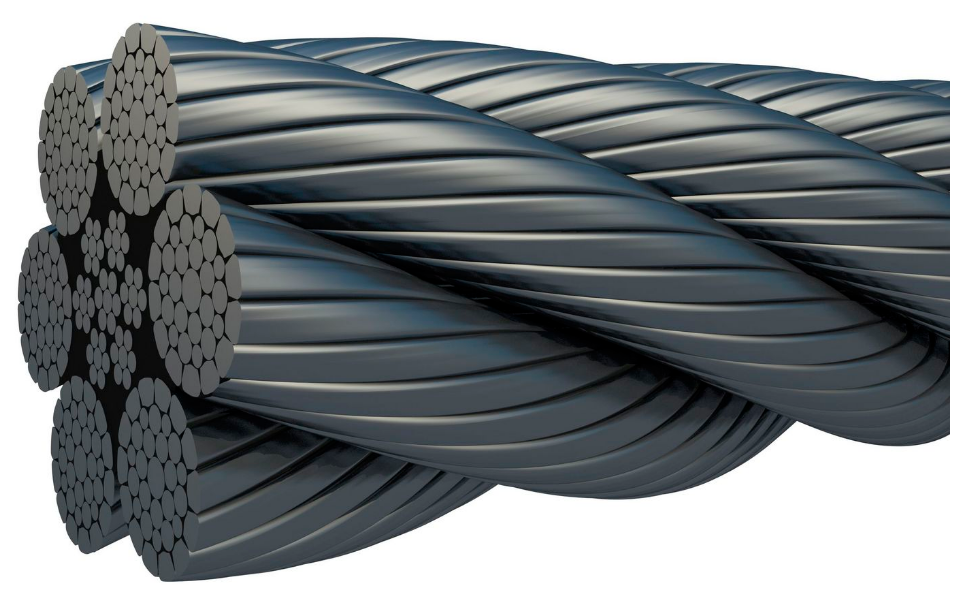

Steel wire rope

Steel wire rope consists of a number of strands and wires that are wrapped around a core in regular geometric shapes, and in choosing the right steel wire rope in cranes, lifts and various industries, the following points should be considered

The diameter of rope -

(Dia) which is stated in millimeters "mm" or inches {"}which must correspond to the drum groove of the device.

Steel wire rope structure -

Construction which is selected according to the function of the device and

: its application

6x7 , 6x12+7FC, 6x24+7FC, 6x17, 6x19, 6x25, 6x26, 6x35, 6x36, 6x37, 6x39, 6x41

8x19, 8x25, 8x36, 8x37, 8x41

7x7 ,7x17, 7x18, 7x19, 7x35, 7x39, 7x40

(Seal, Warrington, standard, Filler) and other different structures

Type of core : Fiber core(FC) or IWRC -

Type of twist: right turn and left turn -

RHOL – LHOL – RHLL- LHLL

grade or tensile -

1370, 1570, 1660, 1770, 1860, 1960, 2160, 2400 N/mm2

IPS, EIPS, EEIPS

Material: Galvanized, non-galvanized, stainless steel (depending on the environment) -

Hot Deep Galvanized

Galvanized

S304- S316L

Lubricant or non-lubricant -

Minimum Breaking Load -

MBL (Minimum Breaking Load): (Lbs, KN, ton)

Standard for producing steel wire rope -

USA API9A, UK BS, Germany DIN, Japan JIS, Russia GOST